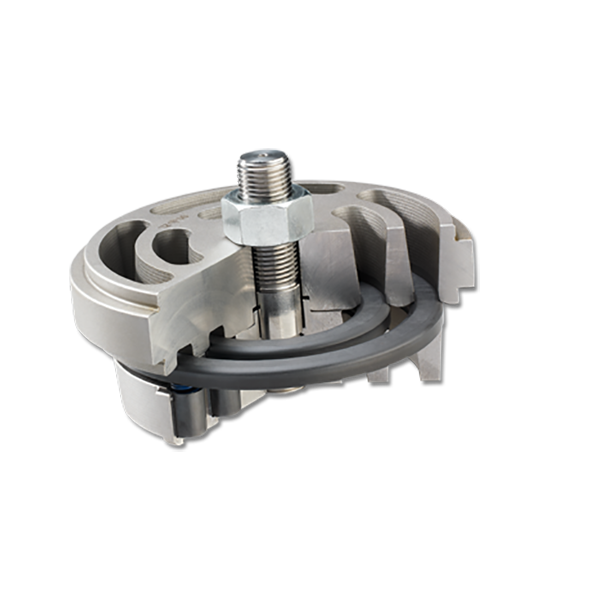

OEM Customized Threaded Ball Valve - CT valve – DONGYI Detail:

FOR USE IN SHORT-STROKE COMPRESSORS AT HIGH ROTATIONAL SPEEDS

High efficiency and long service life

Resistant to gas impurities and oil sticktion

High operating temperatures

The CT valve is suitable for virtually all applications that employ short-stroke, high-speed gas compressors. Primary fields of operation include the transport, production and storage of natural gas. The valves also operate reliably and efficiently in a wide variety of processes in refineries and in the chemical and petrochemical industries.

The design has been tested in practice for years. The plastic valve plate, in conjunction with a spring wave washer, mitigates the opening impact. At high rotational speeds, the spring wave washer prevents oil sticktion of the valve plate. Closing springs on the outside guarantee largely wobble-free valve plate movement and consequently long valve service lives. The seat and flow guidance are resistant to conventional gas impurities. The CT valve can be used both in lubricated and non-lubricated operation.

The valve allows operation up to 1,800 rpm at an operating pressure of up to 350 bars, with a maximum differential pressure of 150 bar. The maximum operating temperature of 250ºC and diameters between 64 and 221 mm (2.5 and 8.7 inches), with a maximum lift of 2.8 mm (0.11 inch), allow a wide spectrum of applications. With the HydroCOM, continuously controlled operation is possible.

TECHNICAL DATA

CT Valve from to

Maximum Pressure 350 bar

Pressure Differential 150 bar

Temperature Range -20°C (-4ºF) +250 °C (+482F)

Rotational Speed 1800 rpm

Product detail pictures:

Related Product Guide:

What’s a 2/2 Compressed Air Valve?

What’s A 4/2 Compressed Air Valve?

To be the stage of realizing dreams of our employees! To build a happier, more united and more professional team! To reach a mutual benefit of our customers, suppliers, the society and ourselves for OEM Customized Threaded Ball Valve - CT valve – DONGYI, The product will supply to all over the world, such as: Miami , Guyana , Slovak Republic , We will continue to devote ourselves to market & product development and build a well-knit service to our customer to create a more prosperous future. Please contact us today to find out how we can work together.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.

-

Factory made hot-sale Ansi Flange Ball Valve - ...

-

Top Quality Ss316 Needle Valve - CONCENTRIC VA...

-

Factory Free sample H07c Piston Ring - CC VALV...

-

Trending Products Air Duct Valve - CS valve &#...

-

Wholesale OEM Small Plastic Air Valves - oil s...

-

Discount wholesale Teflon Ptfe Soft Seal Safety...